HPCF

Hard Polymer Cladding Optical Fibre

Classification:

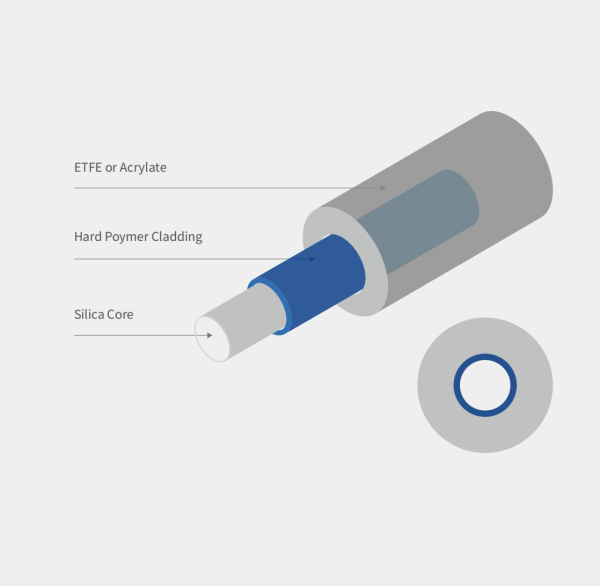

Large core fibre with low OH is suited for 650nm and 850nm apparatus and systems. The hard polymer cladding provides higher tensile strength and greater resistance to moisture. These characteristics determine the HPCF widely used in fields of telecommunication, industry and near-IR spectroscopy environment. Hard polymer (HP) cladding, made up of "fluoroacrylate", plays an important role in protecting glass core. In the process of installation or terminal use, HPCF is hard to break, even under the tightly bend or other rough conditions. Large core with 200μm - 1000μm diameter provides an excellent coupling efficiency for data transmission and connectors. Systems with large core fibre have lower cost due to the loose tolerance characteristics of the components. HPCF shows the best performance applied to short distance medium transmission and data transmission.

Cotnact:

Details Introduction

Applications

• High energy laser transmission

• Short-to-medium distance telecommunication

• Electric signal transmission

• Locomotive traction control

• Medical sensor

• Factory automation control

• Laser therapy and operation

• Near-IR spectroscopy applications

• Optical pyrometry

• Nuclear radiation monitoring

• Optical fibre lighting

Characteristics

• Higher coupling efficiency provided than LED and laser source

• Tolerant of wide fluctuations in temperature and humidity

• More effective connection mode

• Excellent fatigue resistance performance

• Excellent radiation resistance performance

• Compatible with a variety of light source

s

Parameter

Specifications-1

|

Fibre Type |

HP 200/230-37/500E |

HP 200/230-40/500 |

HP200/230-46/500 |

HP 300/330-37/650E |

HP 400/430-37/730E |

|

Part No. |

HP2140-A |

HP2111-A |

HP2112-A |

HP2140-B |

HP2140-C |

|

Optical Properties |

|||||

|

Numerical Aperture |

0.37 ± 0.02 |

0.40 ± 0.02 |

0.46 ± 0.02 |

0.37 ± 0.02 |

0.37 ± 0.02 |

|

Attenuation @850 nm(dB/km) |

≤ 8.0 |

≤ 5.0 |

≤ 8.0 |

≤ 8.0 |

≤ 8.0 |

|

OH Content |

Low OH |

Low OH |

Low OH |

Low OH |

Low OH |

|

Refractive Index Profile |

Step Index |

Grade Index |

Step index |

Step Index |

Step Index |

|

Geometrical Properties |

|||||

|

Core Diameter (μm) |

200.0 ± 3.0 |

200.0 ± 3.0 |

200.0 ± 3.0 |

300.0 ± 6.0 |

400.0±8.0 |

|

Cladding Diameter (μm) |

230.0 + 0/-8 |

230.0 + 0/-8 |

230.0 + 5/-10 |

330.0 + 5/-10 |

430.0 + 5/-10 |

|

Coating Diameter (μm) |

500.0 ± 25.0 |

500.0 ± 25.0 |

500.0 ± 20.0 |

650.0 ± 30.0 |

730.0 ± 30.0 |

|

Core/Cladding Concentricity (μm) |

≤ 5.0 |

≤ 5.0 |

≤ 5.0 |

≤ 6.0 |

≤ 8.0 |

|

Material Composition |

|||||

|

Core Material |

Pure Silica Glass |

Doped Silica Glass |

Pure Silica Glass |

Pure Silica Glass |

Pure Silica Glass |

|

Cladding Material |

Fluoroacrylate |

Fluoroacrylate |

Fluoroacrylate |

Fluoroacrylate |

Fluoroacrylate |

|

Coating Material |

ETFE |

Acrylate |

Acrylate |

ETFE |

ETFE |

|

Mechanical Properties |

|||||

|

Short Term Bend Radius (mm) |

≥ 10 |

≥ 10 |

≥ 10 |

≥ 16 |

≥ 29 |

|

Long Term Bend Radius (mm) |

≥ 16 |

≥ 16 |

≥ 16 |

≥ 24 |

≥ 47 |

|

Operating Temperature (℃) |

-65 to +85 |

-65 to +85 |

-65 to +85 |

-65 to +85 |

-65 to +85 |

|

Proof Test Level (kpsi) |

100 |

100 |

75 |

100 |

75 |

Specifications-2

|

Fibre Type |

HP 600/630-37/1040E |

HP 600/630-37/750E |

HP 1000/1100-37/1400E |

|

Part No. |

HP2140-D |

HP2140-E |

HP2142-A |

|

Optical Properties |

|||

|

Numerical Aperture |

0.37 ± 0.02 |

0.37 ± 0.02 |

0.37 ± 0.02 |

|

Attenuation @850 nm(dB/km) |

≤ 8.0 |

≤ 8.0 |

≤ 8.0 |

|

OH Content |

Low OH |

Low OH |

Low OH |

|

Refractive Index Profile |

Step Index |

Step Index |

Step Index |

|

Geometrical Properties |

|||

|

Core Diameter (μm) |

600.0 ± 10.0 |

600.0 ± 10.0 |

1000.0 ± 20.0 |

|

Cladding Diameter (μm) |

630.0 + 5/-10 |

630.0 + 5/-10 |

1100.0 + 10/-30 |

|

Coating Diameter (μm) |

1040.0 ± 30.0 |

750.0 ± 30.0 |

1400.0 ± 50.0 |

|

Core Concentricity Error (μm) |

≤ 8.0 |

≤ 8.0 |

≤ 10.0 |

|

Material Composition |

|||

|

Core Material |

Pure Silica Glass |

Pure Silica Glass |

Pure Silica Glass |

|

Cladding Material |

Fluoroacrylate |

Fluoroacrylate |

Fluoroacrylate |

|

Coating Material |

ETFE |

ETFE |

ETFE |

|

Mechanical Properties |

|||

|

Short Term Bend Radius(mm) |

≥ 58.0 |

≥ 58.0 |

≥ 73.0 |

|

Long Term Bend Radius(mm) |

≥ 94.0 |

≥ 94.0 |

≥ 118.0 |

|

Operating Temperature(℃) |

-65 to +85 |

-65 to +85 |

-65 to +85 |

|

Proof Test Level (kpsi) |

75 |

75 |

85 |

Documents

Previous Page

Next Page

Keyword:

Hard Polymer Cladding Optical Fibre

Production

Related Products

Message consultation

We will surprise you with a gift as soon as we receive your message.

Contact Information

Add: 9th Floor, Building B, Optics Valley Times Square, No. 111 Guanshan Avenue, Donghu New Technology Development Zone, Wuhan